Construction, Demolition and Mining sites (as required by AS/NZS 3012:2010) and tools in site vehicles (as this is considered a harsh environment and therefore appliances are more likely to be damaged and subject to abuse than in other settings).

Should My Commercial Appliances Be Tested & Tagged?

Should My Commercial Appliances Be Tested And Tagged?

Electrocution or arc flashes can cause fatal consequences when working near electricity or when using electrical appliances. Regular testing of your commercial appliances can highlight safety issues and safeguard your staff.

Is It A Legal Requirement To Test And Tag Electrical Equipment?

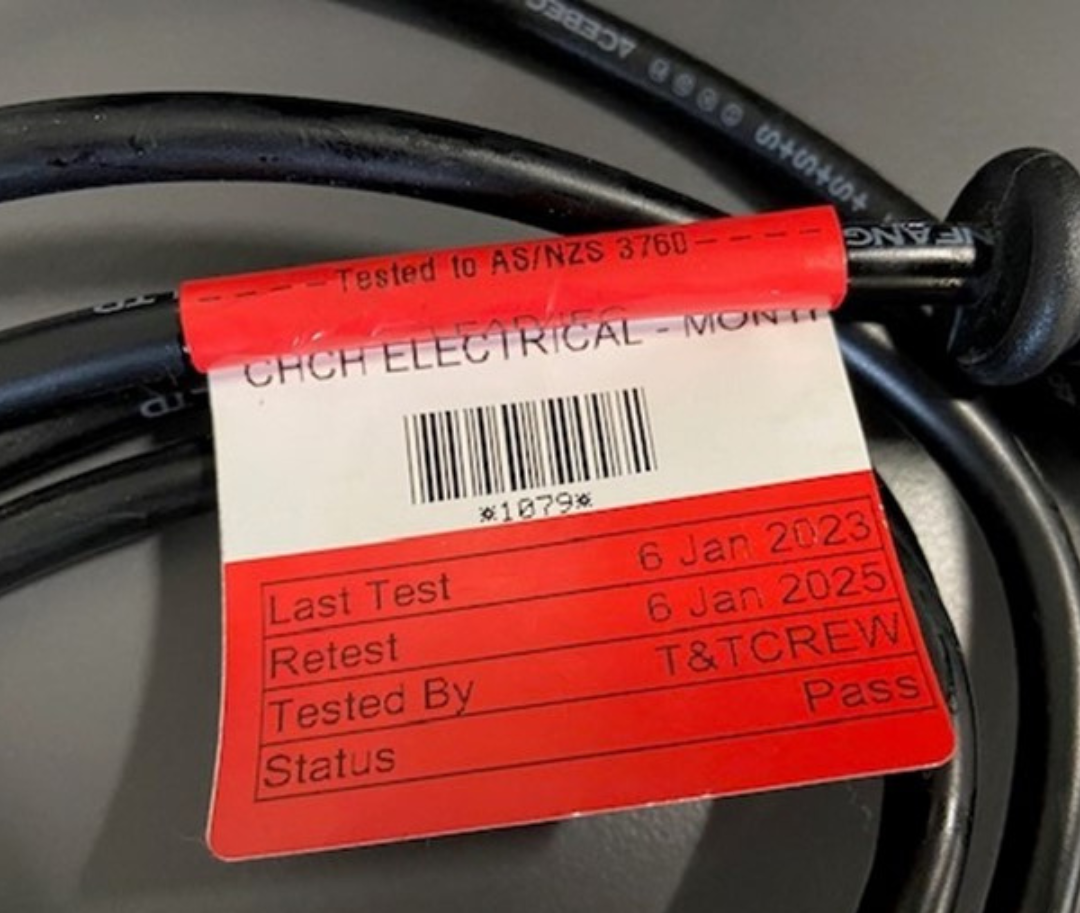

It is a legal requirement to ensure electrical equipment is electrically safe and maintained in a safe condition (this includes all NEW appliances when first introduced into service unless supplied through an electrically safe RCD, or portable residual current device (PRCD) which itself has a current tag).

Regulation 26 of Electrical (Safety) Regulations 2010 (ESR) (26) only states one simple way to verify the safety of appliances that owners make available to their employees, contractors or are hired out, is to have the appliances tested and tagged in accordance with standard AS/NZS 3760.

What Type Of Equipment Should Be Tested And Tagged?

All electrical equipment that is plugged into a low voltage power supply (including single and three phase appliances and leads) should be tested and tagged:

For example:

- Portable outlet devices or power boards

- 3 phase machines on factory floors not permanently wired

- Portable transformers & RCD power boards

- Battery chargers

- Portably heavy-duty hand tools

- Flexible cords (the interval of inspection and testing is dependent upon the environment the cord is in, e.g., low or high risk of damage)

- Basically, anything that can be and or is plugged into a power supply

This also includes:

- Any plugged appliance, single and three phase, where the flexible supply leads are flexed during normal use, open to abuse or in a hostile environment

- Fixed RCDs in a switchboard

How Often Should Appliances Be Tested & Tagged?

The frequency to test and tag an appliance is primarily determined by the nature of the equipment and the environment that the appliance is in.

In contrast to an office computer, electrical equipment used on construction sites (outdoors in damp or hostile environments) would need to be tested more often.

The AS/NZS 3760 standard is a minimum test and tag frequency. Individual workplaces may have different test and tag frequency rates based upon their unique risk management and health & safety planning.

Standard recommended frequencies are as follows for the most common environments:

Who Can Carry Out Electrical Test & Tagging?

To complete the task correctly, a trained/experienced test and tag technician or electrician is required. The individual performing the work must have the necessary knowledge and skills (as listed in AS/NZS 3760) and be able to understand the Standards involved.

A registered electrician or electrical service technician will be required to remedy any failures requiring electrical repair that the testing reveals.

Tips To Increase Safety & Reduce Tagging Costs

Taking a few simple steps can reduce the time taken to carry out test and tagging, allow for your tagging frequency to be extended in some circumstances, as well as reduce the risk of electrical fire.

- Ensure regular cleaning under desk areas. Remove any dust build ups including on power boards

- Keep leads tidy, out of the way of traffic areas, and untangled

- Do not use travel adapters for permanent use

- Fit power boards under desk where possible

- Do not use home grade extension leads in a commercial setting – use leads fit for purpose

- Do not crush leads or plugs (E.g., pushing appliances such as fridges against plugs)

- Ensure leads for tagging are accessible without obstruction

Looking for a trusted and specialised electrical service company to test and tag? Christchurch Electrical test and tag electrical appliances in Christchurch and the wider Canterbury region. Call (03) 366 1718 to make a booking.

Share article: