Who Can Carry Out Electrical Test and Tagging?

How Can I Check the Electrical Safety Of My Appliances?

Regularly, visually check cords, plugs and tools to see if they are damaged. Encourage staff to report and check faulty damaged equipment and to check dates on existing tags.

Remember that in certain circumstances, electrical equipment requires an RCD (Residual Current Devices), for outside or in damp areas. Maybe Image

If you find any items considered dangerous or damaged, remove the appliance from service and contact

Christchurch Electrical to arrange one of our qualified Electrician’s to remedy the issue.

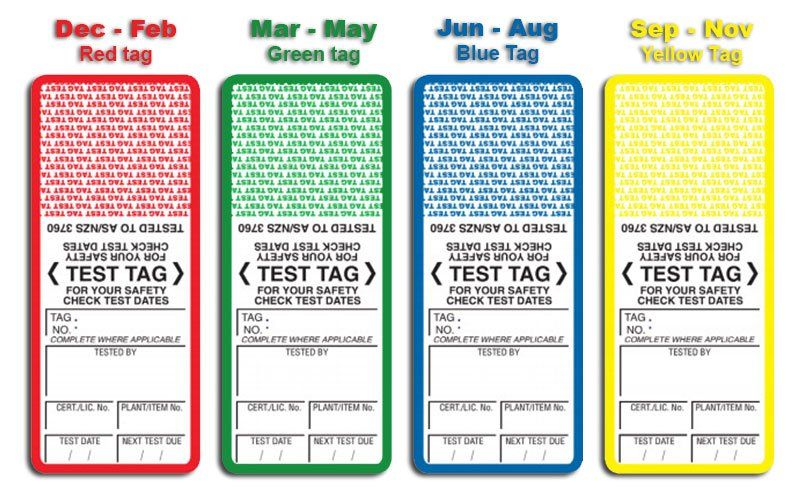

Test & Tag Colours

There are two key environments that determine the colour of your electrical appliance test tag:

• Construction, Demolition or Mining: for these environments, specified test tag colours are required

• Other industries: no specified colours required – you can decide your own colour coding

AS/NZS 3012 recommends all construction, mining and demolition equipment to be tested every 3 months and tagged using a time-specific colour

Our Test & Tag Services

- Pre-site assessment and advice recommending savings and explanation of the testing process

- Conduct visual checks of electrical appliances and leads for defects or possible damage

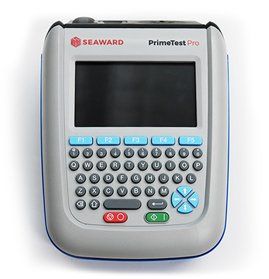

- Electrical testing performed with a PAT (Portable Appliance Tester) including:

- Single phase testing

- Three phase testing

- RCD testing

- Tagging of appliances and leads with due dates (including the use of plastic tag covers for tough environments)

- Identify failed items and make safe

- Comprehensive report provided including all items tested and their pass/fail status, recommendations for safety improvements, cost saving recommendations including how to reduce tagging intervals in office environments and recommendations for replacement of older equipment

- Testing data retained for 7 years (as legally required)

- Lead repair & replacement

- Repairs of failed appliances (basic repairs maybe completed on site, substantial repairs may need to be separately reviewed or quoted)

- Retest due reminders

Top Tips To Increase Safety & Reduce Tagging Costs

Taking a few simple steps can reduce the time taken to carry out test and tagging, allow for your tagging frequency to be extended in some circumstances, as well as reduce the risk of electrical fire.

- Ensure regular cleaning under desk areas. Remove any dust build ups including on power boards

- Keep leads tidy, out of the way of traffic areas, and untangled

- Do not use travel adapters for permanent use

- Fit power boards under desk where possible

- Do not use home grade extension leads in a commercial setting – use leads fit for purpose

- Do not crush leads or plugs (E.g., pushing appliances such as fridges against plugs)

- Ensure leads for tagging are accessible without obstruction

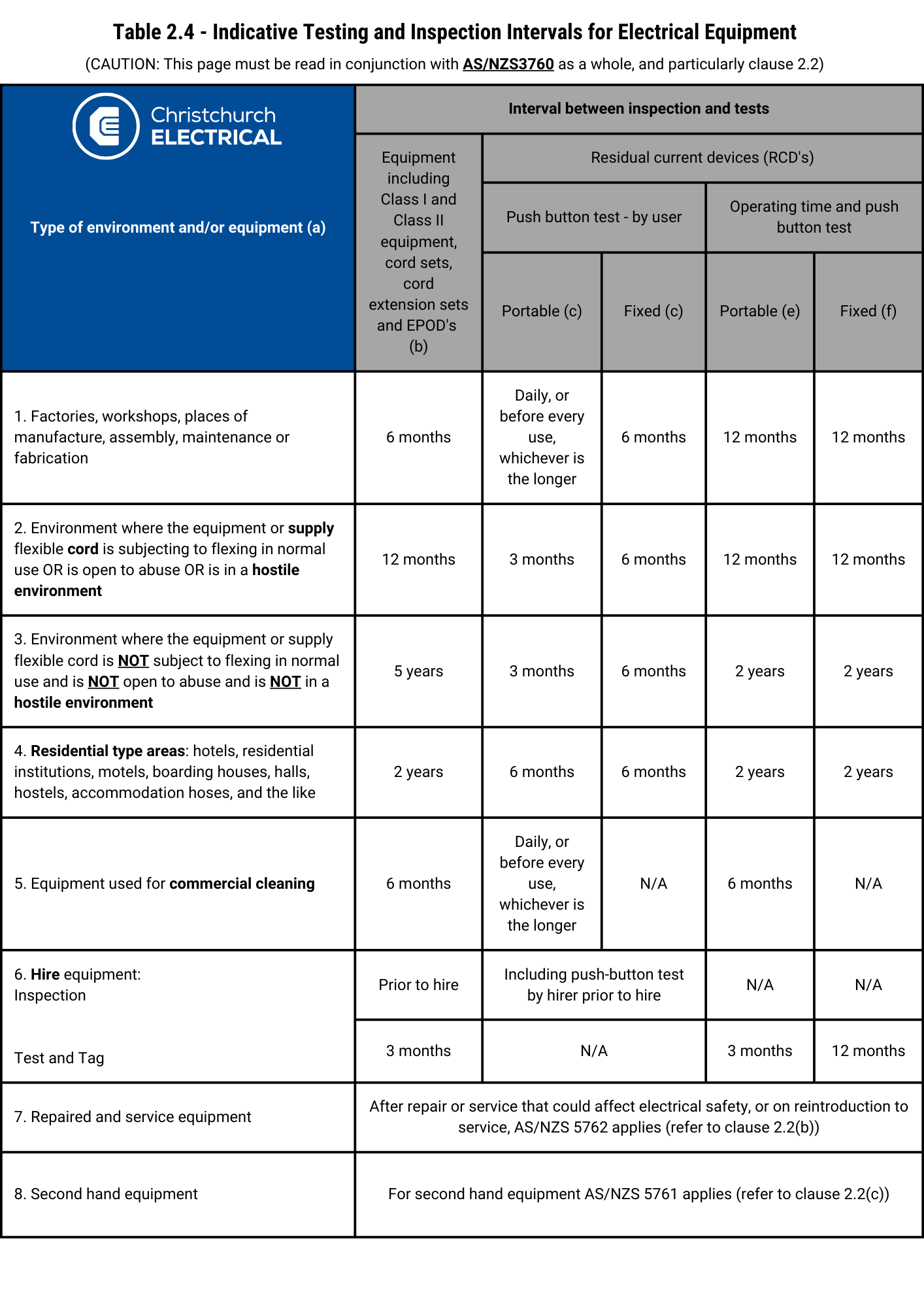

Test and Tag Intervals – AS/NZS 3760 – Table 2.4

In accordance with the standard ASNZS 3760 that regulates the industry in New Zealand, the intervals below are recommendations. They should be considered as minimum requirements for PAT tests.

Ensure A Safe Workplace – Schedule Electrical Testing

Electrical appliances will be reviewed by experienced technicians to ensure they are safe to use at time of testing. They have the skills, experience, and equipment to carry out testing in accordance with the AS/NZS 3760 standard and conduct necessary repairs. Appliances are visually inspected for defects such as damage or missing components, as well as electrically tested for earth continuity, insulation resistance, and polarity.

Looking for a trusted and specialised electrical service company to test and tag? Christchurch Electrical test and tag electrical appliances in Christchurch and the wider Canterbury region.

Call (03) 366 1718

to make a booking.